Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Pulsation & Mechanical Analysis: Reciprocating Compressor

Pulsation study, mechanical review and frequency avoidance analysis, forced response analysis (when required); per API 618, API 688 and GMRC High-Speed Compressor Guideline.

For compressors below 750 RPM the study is conducted per API 618 requirements, the pulsation and vibration standard for slow-speed compressors.

For higher-speed compressors, the GMRC High-Speed Compressor Guideline and API RP 688 are used to define the vibration requirements. The GMRC guideline is based on the API standards but has been augmented for the unique requirements of higher-speed compressors.

This pulsation and mechanical analysis is applied during the design stage. Along with this analysis, it is common to also have a torsional vibration analysis, small-bore piping analysis, and other related engineering studies completed for a compressor package.

Contents [ hide ]

1 Scope

A vibration study includes different design components, depending on the risk and application. The standard requirements often include:

- Pulsation and Mechanical Analysis (see 1.1 and 1.2 below)

- Torsional Vibration Analysis (TVA)

- Pipe Stress Analysis (Thermal/Piping Flexibility Analysis)

- Small-Bore Connections (SBC) Assessment

Depending on the application, the following studies may be required:

- Skid Design and Analysis

- Foundation Design and Dynamic Analysis (onshore)

- Structural Vibration and Dynamic Design (OFFSHORE)

These services are typically bundled together to address all vibration risks associated with the compressors, including the off-skid piping system. Note that Wood can also support in managing vibration on pumps and associated piping systems at your facility.

The following two steps will help you determine which services are required for your compressor application:

- Determine the risk category for the application. Contact our application support for assistance or use Wood's (BETA) Risk Rating Chart (Excel)

- Based on the risk, determine the recommended scope of work. For more about the scope and options, see Design Requirements for Reciprocating Compressors

1.1 Pulsation (Acoustical) Analysis

| Reduction in pulsation forces | |

|---|---|

| As found Piping System (No Pulsation Study) |

After Wood Pulsation Study (Using Time Domain Solver) |

|

|

|

Forces above 11,000 lbf |

Forces below 200 lbf, well below guideline |

Pulsation (Acoustical) Analysis applies to “medium” and "high" risk units.

See our Risk Rating Chart (Excel)

|

|

|

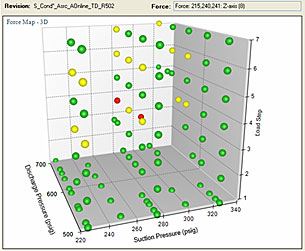

DataMiner™ post processing tool analyzes pressure pulsations, forces and other vibration issues – across hundreds of conditions and locations in the piping system. See why DataMiner provides extra value for your projects. Read more |

Features include:

- Bottle Sizing An Online Bottle Sizing Tool is available as a starting point for compressor layouts. To enable early ordering of heads and shells, Wood can complete a more detailed pulsation bottle sizing assessment in 2-4 business days (typically).

- Performance Verification A compressor performance analysis can be used to assess the compressor’s operation across the entire operating envelope.

- The standard service is to evaluate up to 20 operating conditions.

- CAUTION: For some applications, the operating map cannot be thoroughly evaluated with just 20 points. Some important regions will be missed and could result in excessive pulsations. In these cases, additional conditions should be evaluated (see option 1.3, below).

- Wood will assess pulsations and other dynamic loads for the supplied conditions, including pressures, temperatures, gas composition, clearances, valve unloading and speed ranges.

- Pressure Pulsations Wood will assess the magnitude of pressure pulsations and pulsation-induced shaking forces in the piping system using its MAPAK simulation software. Time Domain acoustic simulation is recommended for a more accurate pulsation analysis, as compared to the older Frequency Domain approach. More on pulsation software

- Pulsation Control Pulsations are controlled using acoustic filters, bottles, orifice plates, resonators and/or piping modifications. Pulsations (pressure and forces) are controlled to API 618 (most recent edition) or other field proven guidelines.

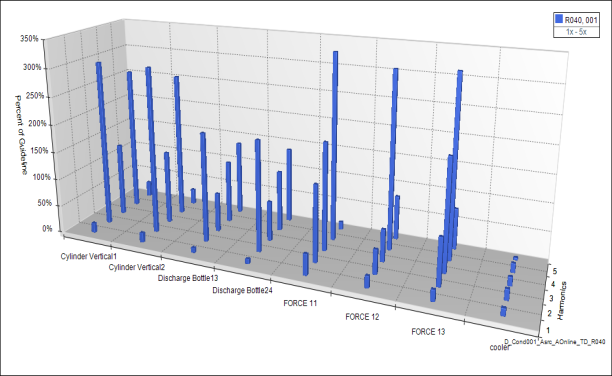

- Cylinder Forces Pulsations forces between the cylinder and pulsation bottles are also evaluated using Wood’s guideline, an advantage over other approaches.

- Pressure Drop As a standard feature, Wood will assess static and total pressure drop (per API 618 guidelines) for pulsation control devices such as orifice plates and choke tubes. Total pressure drop includes dynamic pressure drop losses. The impact of pulsation control on compressor load is evaluated and included in the report results.

- Piping Restraint Analysis (Mechanical Review) This includes an evaluation of pipe support locations using charts, empirical calculations and good engineering design practices.

- Results and Reporting Wood’s DataMiner software tool and reporting approach provide valuable information on the compressor’s pulsation predictions and performance.

|

|

|

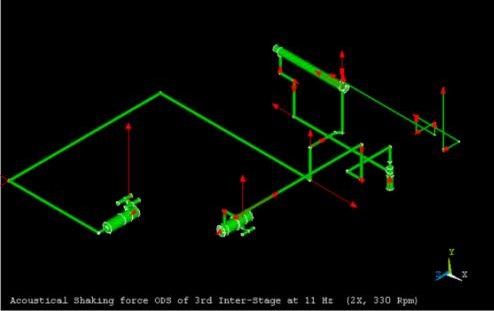

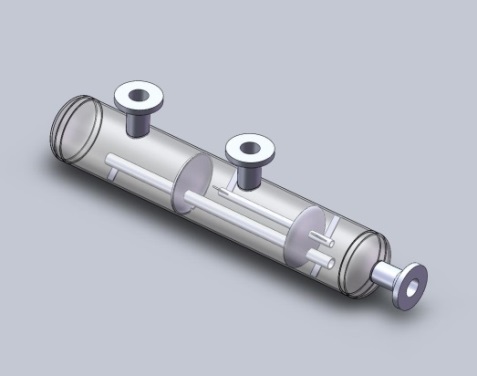

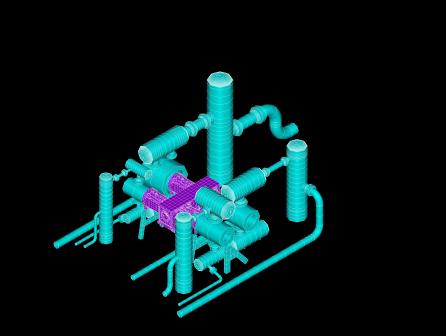

The acoustic model of the piping system (left) is used to determine pulsation pressure and unbalanced forces at all operating conditions and locations in the system. This example illustrates the 3rd interstage system. The red arrows represent the magnitude of the forces. Pulsation control bottles (right) contain choke tubes, baffles and volume chambers. This will filter and dampen pulsation and reduce forces to acceptable levels. |

|

1.2 Mechanical Analysis

1.2.1 Frequency Avoidance

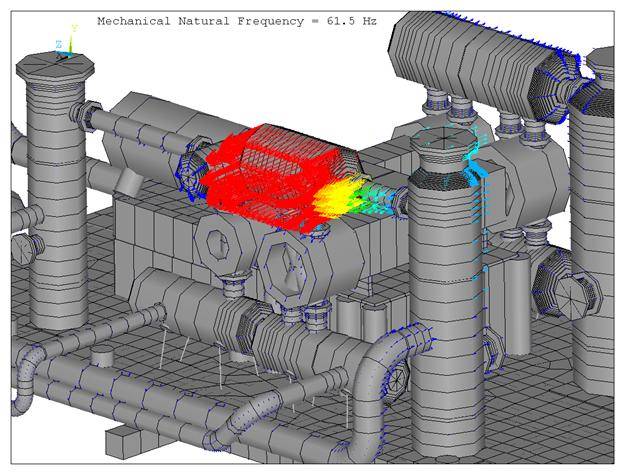

The first step in a mechanical analysis is to determine the Mechanical Natural Frequencies (MNFs) in the system, identify where and when resonance may occur, and provide recommendations to improve the design.

This study is part of a Design Approach 3 (DA3) per API 618 terminology and includes the following features:

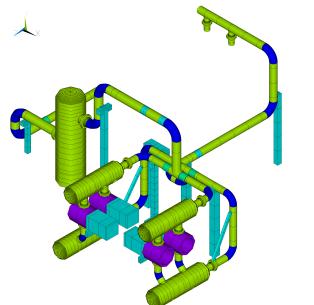

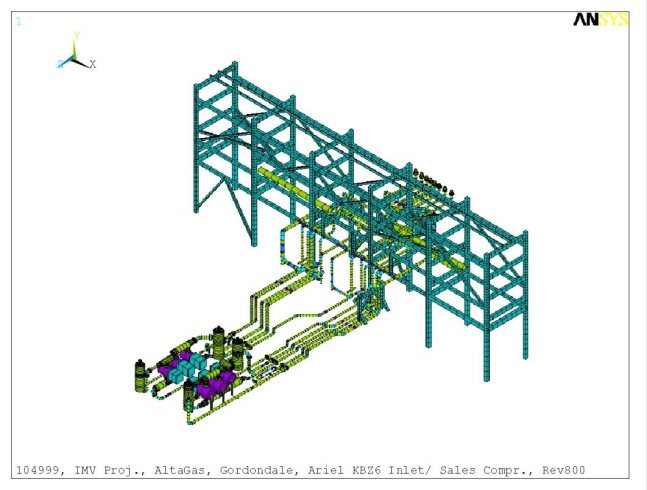

- Finite Element (FE) Model Wood will quickly generate an accurate FE model of the compressor, vessels, piping system and key areas of the skid (if applicable). For even more accurate results, a detailed model of the compressor frame and/or the full skid and foundation can be included in the model. Wood uses ANSYS for all FE models to ensure accurate results. Some piping FE analysis programs are not recommended for this application.

- Accuracy Complex geometries are accurately modeled using shell or solid elements. Rotational inertias are included. Boundary conditions such as scrubber base connections and cylinder details are accurately modeled based on Wood’s database from over 40 years of field testing actual compressor cylinders for most OEM’s.

- Mechanical Natural Frequencies (MNFs) The MNFs and mode shapes are determined for the key components in the system, with results published in the report.

- Frequency Avoidance MNFs shall have a 20% margin of separation above 2X compressor run speeds, and 20% away from other orders that have significant forces.

- Results and Report A detailed report is provided, summarizing recommendations and mechanical results.

Find out more in this video: Mechanical Analysis for Reciprocating Compressors (Video)

|

|

|

|

|

A mechanical analysis requires accurate FE models (above) of the compressor piping system to determine MNFs and avoid resonance. Models are also used in Forced Response Studies (option below) to determine vibration and stress amplitudes. Field experience and measurements are required to accurately define boundary conditions, dynamic forces, and practical recommendations to avoid problems. |

|||

1.2.2 Forced Response Analysis

This analysis is required by API 618 when frequency avoidance recommendations cannot be achieved or implemented. The study includes all significant compressor forces (including cylinder gas forces, pulsation forces, torsional to lateral excitation – options noted below, etc.) and will evaluate vibration and stress to API 618 guidelines. There are two locations where this option is conducted:

- Compressor Manifold System (step 3b1, formerly study M.6 per API) involves analysis of the bottles, scrubber, and piping around the compressor frame; and

- Piping away from the Manifold (step 3.b.2 Piping Dynamic Stress Analysis (formerly study M.7). This is recommended when the pulsation force guideline cannot be met, or the Frequency Avoidance Analysis recommendations cannot be implemented.

1.3 Options

The following options are often added to the API 618 Design Approach 3 (DA3) study (or GMRC High Speed Guideline) described in Sections 1.1 and 1.2:

-

Small-Bore Connections (SBC) Wood provides a range of services to design, analyze, and test SBC, depending on the application and customer’s risk tolerance. For SBC service options

- Additional Operating Conditions (beyond the 20 conditions included in the standard study). For some applications defining 20 operating points will not sufficiently cover the range of operating conditions and load steps to ensure all potential pulsation and vibration problem areas are evaluated. Wood can provide assistance in defining the recommended number of conditions to analyze.

- Torsional to Lateral Excitation Evaluate the risk of torsional to lateral excitation on the compressor frame and manifold, vibration impact and mitigation options. This feature is recommended for high horsepower applications. When Wood conducts the torsional analysis, this service fee is minimal because there is close integration between torsional and mechanical analysis. The forces created by the torsional response of the crankshaft are calculated and are included as additional input in the forced response analysis. By including ALL significant forces acting on the compressor, Wood evaluates the vibrations and stresses as a system.

- Off-skid or Station Piping Wood will assess pulsations in piping away from the compressor package (if information is available). This added level of analysis is valuable when coolers and/or scrubbers are located away from the compressor package, or when pulsations need to analyzed in the headers and plant piping system.

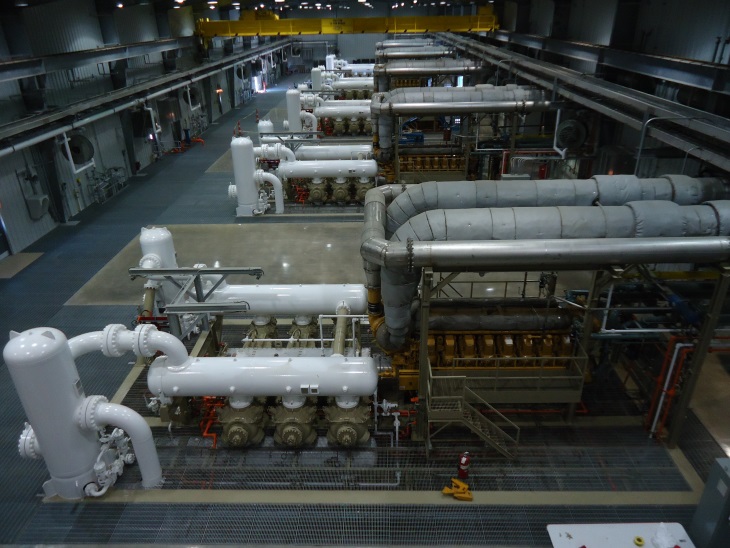

- Multi-unit Analysis (Interaction between units) When multiple compressors are connected together in series or parallel, Wood will evaluate pulsations in headers and plant piping system, including interaction between units. This option applies to multiple reciprocating compressors, or a combination of reciprocating and centrifugal compressors.

- Pulsation Power Loading (System Performance Analysis) Pulsation control will result in pressure drop and power losses in the piping system. For a more accurate understanding of the power loss and the impact on compressor performance, this option will evaluate the pulsation loading in the entire piping system (including pulsation control elements). An updated compressor performance report is then provided, based on the accurate understanding of pulsation losses. This service is valuable to ensure the driver/compressors are adequately sized for critical applications such as pipeline compressors.

The following options are occasionally required:

-

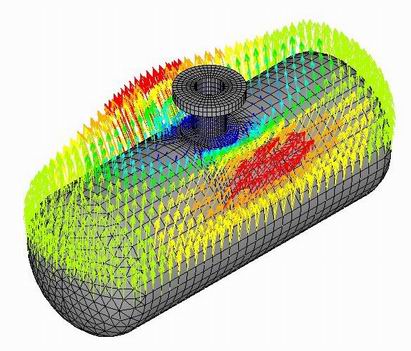

Vessel Internal Stress Calculation (formerly called M8, per API 618). This analysis applies pulsation-induced shaking forces and pressure-induced static forces to the shell and vessel internals and calculates stress levels.

- Compressor Valve Dynamic Analysis (formerly called M9, per API 618). This limited analysis will ensure that compressor valve natural frequencies are not within +/- 10% of any acoustical resonances and that pulsation levels at the valve do not exceed 2% of the line pressure at frequencies within +/-10% of the valve natural frequency. The full (enhanced) analysis will evaluated the interaction between the compressor valves and system pulsation.

- Low Cycle Fatigue Analysis (formerly called M10, per API 618). This analysis is used to predict the stresses from thermal gradients, thermal transients, and pressure cycles on the pulsation-suppression devices and internal components when required by Division 2 of the ASME code. The stresses are compared to ASME-code.

- Fuel Gas Booster Compressor - Receiver Sizing/Transient Study This analysis will size a receiver to prevent transient starvation-induced surge on a centrifugal compressor due to a sudden reduction in upstream pressure (often as the result of the loss of a reciprocating compressor). Wood will review the customer’s compressor control system logic and response characteristics and determine the appropriate system capacity between the reciprocating compressors and the centrifugal compressor to ensure surge will be avoided. Read more

- Transient Surge Analysis of ESD Piping (Gas Blow Down) With high pressure application such as gas storage with multiple compressors, high ‘fluid hammer’ forces and vibration will be generated when blow down valves are opened for ESD. The blow down analysis will help to determine the sequences and time interval of opening of blow down valves, and vibration impact to piping and supports. Wood will provide recommendations to control the time required for blowdown.

|

_on_pulsation_bottle_-_small.jpg) |

_small.jpg) |

| Modal Analysis on pulsation bottle showing MNF and mode shape. | Low-cycle fatigue analysis (M10) on pulsation bottle. | Vessel internal stress calculation (M8). |

2 Wood Advantages

We are the global leader in pulsation analysis because of these unique factors:

|

- VDN (formerly BETA) pioneered the development of digital acoustic simulation in the 1970s. Every year since then, the Company makes significant investments in acoustic simulation tools and field-based verification to ensure its MAPAK software is world-class. This Time Domain-based simulation includes non-linear fluid dynamics and time-varying boundary conditions; an important feature for modeling higher frequency acoustics. This important feature is not available with commercially available software used by small firms.

- More standard features, including improved performance analysis, more accurate boundary conditions, and improved analysis of off-skid piping

- Better quality control and project management expertise. A focus on quality, technical reviews, and effective client communication yields a more successful project.

- Responsive application advice and ongoing customer service.

- Studies are compliant with API 618.

- Timely and practical recommendations

- Wood has a full-time field engineering team to assist with start-up checks or onsite support on a global basis

- Pulsation and mechanical vibration modeling techniques are field verified. Other firms provide theoretical results because they lack full-time field engineers who provide the necessary field input and model verification into the design process.

- Local support by experts located in the US, Canada, Malaysia, China, Australia, UAE, Saudi Arabia, and the UK

- Wood offers a fully integrated vibration solution – including compressors, pumps and piping design and field support. This approach ensures you meet your reliability and integrity management requirements.

- Wood conducts industry research projects for the Gas Machinery Research Council. As a result, Wood has gained superior knowledge and expertise

- Active member in API and GMRC vibration task force committees

3 Client Benefits

As the global market leader in compression design services, Wood is able to offer a number of unique services and features, including accurate pulsation and mechanical analysis that benefit the packager, OEM, and customer. These benefits include higher system reliability, minimized pressure drop and performance losses, faster turnaround in the design, optimized vessel sizes, and lower overall costs.

Other benefits include:

- Pulsation forces controlled throughout the piping system

- Piping and vessel vibration minimized

- Complete range of operating conditions evaluated

- Recommendations provided that represent a balance of all competing requirements (pulsation control, added pressure drop, mechanical constraints and practicality of implementation)

- Effective reporting and analysis for useful field analysis and monitoring

4 Related Information

- Risk rating chart (to assess vibration risks, and recommended scope for your project)(EXCEL)

- Tips for managing a successful vibration project

- Recommended Guidelines and References

- Specification for purchasing a vibration design study (PDF)

- Background on API 618 pulsation and vibration studies (pdf)

- Bottle Sizing Service (free online service)

Pipe Clamps for Vibratory Loads

Pipe Clamps for Vibratory Loads- Application Guide For Discharge Bottle Supports (PDF)

- Videos and animations

- Training Courses

Popular Articles:

- Pipeline Station Pulsation Case Study (pdf)

- Design Challenges for Reciprocating Compressors in Specialty Gas Services (pdf)

- Torsional Vibration Case Study Highlights Design Considerations (pdf)

- GMRC Project: Equipment Mounting - Stiffness Testing of Different Chocks and Support Designs (2014)

CompressorTech2:

5 Free Webinar

Learn how to avoid pulsation pitfalls in suction and discharge piping systems in our free on-demand webinar

6 Related Services

Common studies that may be coordinated with the Pulsation & Mechanical Analysis:

- Small-Bore Connections (SBC) Assessment

- Torsional Vibration Analysis (TVA)

- Pipe Stress Analysis (Thermal Flexibility Study)

- Skid Design and Analysis

- Foundation Design and Dynamic Analysis

- COMPRESSOR PACKAGE Engineering Services

Keywords

- API 618

- API 688

- Acoustic analysis

- Acoustical analysis

- Acoustic study

- Pulsation study

- DA2, DA3, M2, M4, M5, M5, M7

- Forced response

- Analog study

- Pulsation analysis

- Compressor pulsation

More Info

Webinar: Vibration problem solving – back to basics • Multi-channel vibration measurements • Five simple methods to check reciprocating compressor performance • Webinar: Feeling the pulse • Design Requirements for Reciprocating Compressors • Machinery Condition and Performance Monitoring • Evaluating Compressor Operating Risks • Tips for Managing a Successful Vibration Project • Specifications •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now