Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Multi-channel vibration measurements

Advanced post-processing tools turn vast amounts of data into actionable insights

|

|

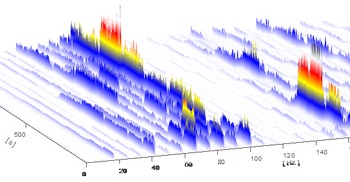

| Waterfall representation of a compressor speed sweep – vibration amplitudes during long-time capture |

Due to changing pipeline flow requirements and flow reversal trends in the natural gas industry, it is often necessary to modify the compressor stations feeding the pipelines. Sometimes, different operating pressures or additional load steps are required. In other cases, new compression, meter stations or coolers may be added. These changes can inadvertently create pulsation and vibration problems in the station.

Changing compressor load steps or pressures will alter the flow from each unit as required, but this will also modify the pulsation source amplitudes originating at the compressors, both on the suction and discharge systems.

Piping changes in the station will create different acoustic resonances. Each of these factors can cause a station that has run smoothly for decades to suddenly develop vibration problems. To prevent potential vibration problems when changing operating conditions, a pulsation simulation study is recommended. However, options to control pulsation are limited, as existing pulsation bottles cannot be reconfigured to new conditions. As a result, many stations end up experiencing pulsation exceeding API 618 allowable amplitudes.

Full article (CompressorTECH2)

The best way to ensure that these pulsations do not result in excessive vibration and fatigue failures is to measure vibration levels within the station, so that problem areas can be mitigated.

The best way to ensure that these pulsations do not result in excessive vibration and fatigue failures is to measure vibration levels within the station, so that problem areas can be mitigated.

Continue reading in CompressorTECH2

About the author

Wally Bratek, MSc, PEng

Principal consultant, vibration, dynamics and noise

Wood

|

Wally has more than 20 years’ design and field experience including acoustical (pulsation) and mechanical vibration analysis, field testing and troubleshooting, and lateral rotordynamics. He has presented multiple papers at industry conferences, is a member of the GMRC Gas Machinery Conference Planning Committee, and is an active member of the API 618 6th Edition task force for pulsation analysis. |

Related Pages

Field engineering and troubleshooting • Vibration-induced fatigue management (Offshore Magazine) • Avoiding vibration-induced fatigue failure • Five simple methods to check reciprocating compressor performance •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now