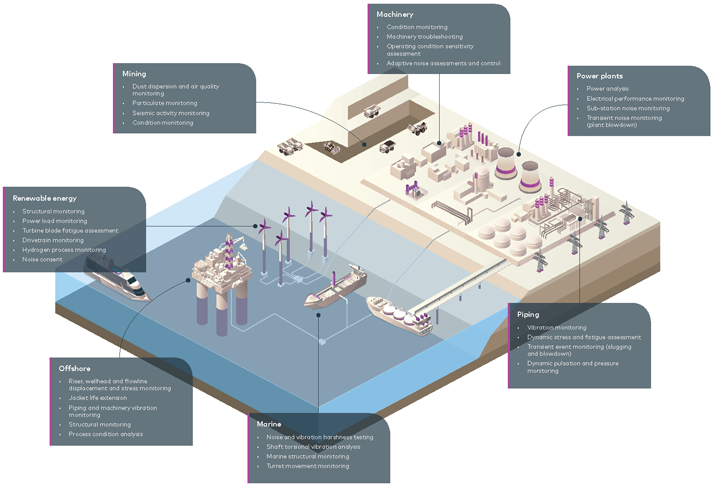

| Machinery |

|

| Power plants |

|

| Piping |

|

| Marine |

|

| Offshore |

|

| Renewable energy |

|

| Mining |

|

| Infrastructure |

|

Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Veridian iDAC

Intelligent data acquisition

Veridian iDAC is Wood’s intelligent data collection solution that brings you the latest advances in acquisition hardware coupled with leading-edge analysis techniques.

The versatile device provides a cost-effective, safe and enduring monitoring solution for energy, chemicals and resource assets and industrial machinery.

The system operates remotely without the need for costly on-site support, making it ideal for short and longer-term assessments and remote locations.

Contents [ hide ]

1 Applications

- Machinery

- Power plants

- Piping

- Marine

- Offshore

- Renewable energy

- Mining

- Infrastructure

Download the flyer for more details.

2 Available modules and features

Veridian iDAC can be configured to your needs with a combination of these modules:

|

Core system The fully functional core system stores data locally and records autonomously for the duration of the installation – intervention and maintenance-free. |

|

Advanced sensor technology Customizable solution for all your measurement needs, through leading-edge technology partners. |

|

Remote connectivity Remotely accessible from anywhere in the world – allowing for installation in remote locations and live streaming of data worldwide. |

|

Extreme conditions Can be configured for extreme temperatures, pressure, wind and humidity – allowing for installation in the most extreme environments. |

|

Intrinsically safe For monitoring in hazardous areas, Veridian iDAC can be designed to be intrinsically safe – from enclosure to sensor. |

|

Independently powered By incorporating alternative power sources such as wind or solar, the system can be deployed in areas where standard power sources may not be available. |

|

Control system integration Full integration with your operating system – data can be fed back into your control systems (DCS), ensuring the safety and reliability of personnel and critical machinery. |

3 Benefits

- Safe, easy and fast setup

Reduced number of cable runs and faster installation - Peace of mind

Records continuously; problems can be identified as they occur - Increased reliability

Improved identification and analysis of potential problems - Cost savings

Significantly cheaper than using traditional staffed site surveys can be correlated to process conditions, allowing operations to respond quickly - Expert support

Our experts can help monitor, analyse and interpret data, providing better and faster solutions - Better control of process parameters

Issues can be correlated to process conditions, allowing operations to respond quickly - Advanced analysis

Our wide range of in-house advanced analysis capabilities can help solve the most complex problems (if required)

4 How to rent or purchase

Contact our experts for more information and pricing.

5 Webinar

Insight out

Insight out

Technical considerations and best practices for specifying a remote data acquisition system and overview of our data collection solution Veridian iDAC.

6 Related information and services

Veridian vibration screening and assessment software

Field engineering and troubleshooting

-

View list

-

Applications

[ACCORDION_1]

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now