Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Foundation Design and Dynamic Analysis

Including Concrete, Gravel, and Piles

Wood provides static and dynamic foundation design services for machinery systems. In addition to including machine loads, we evaluate local soil conditions (allowable bearing capacity, static settlement guidelines, etc.) and compatibility with the site characteristics such as frost heave potential.

|

|

|

Example of cracked foundations, causing vibration and equipment reliability problems. |

|

Contents [ hide ]

1 Scope, Features, and Benefits

|

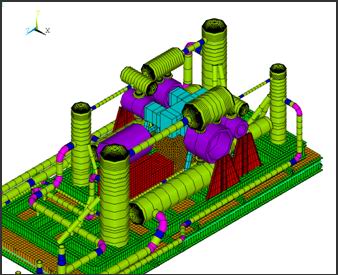

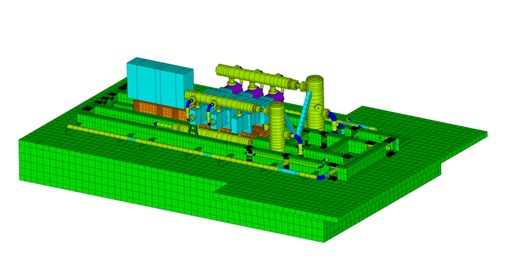

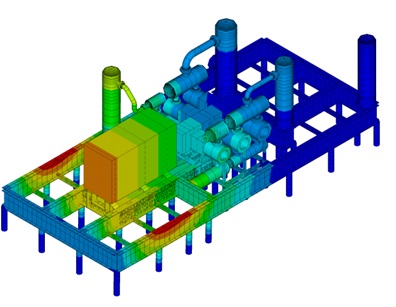

| Skid, Compressor, and Foundation Analysis |

|

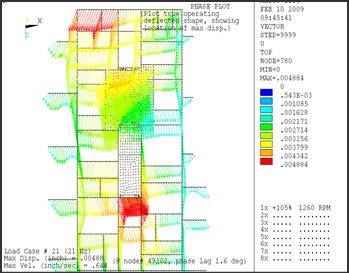

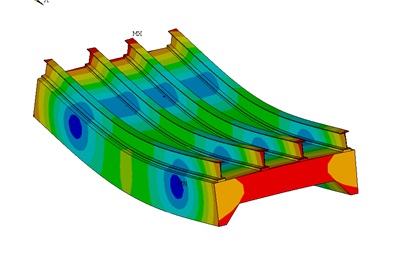

| Top view of operating deflection shape |

|

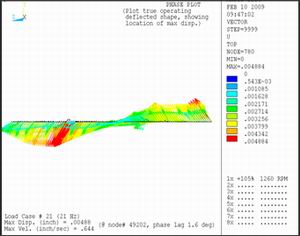

| Side view of operating deflection shape |

1.1 Scope

In each project, we:

- Optimize the dynamically loaded foundation by considering all types of foundations.

We have experience with:

- Concrete blocks

- Gravel pads

- Piles

- Screw Piles

- Table top

- Hybrid (concrete and piles)

- Structural foundations (FPSO, offshore platforms, steel modules/structures)

- Design and assess foundations for all types of machinery systems

- Include new and remediation/revamp projects

- Provide solutions to existing vibration problems

- Account for geotechnical considerations at the site

- Evaluate dynamic loading across all operating conditions

1.2 Features Include

- Accurate determination of dynamic loads caused by equipment and the effects of such loads taking into account the soil and structure interaction.

- Identification of area soil conditions (working directly with local geotechnical companies) for design projects.

- Assessment of the foundation’s natural frequencies, damping characteristics, and potential resonance conditions, as well as the impact of vibration and dynamic stress.

- Field measurements taken for existing foundations, to help define soil properties to insert appropriately into our models.

- Recommended foundation design to limit vibration to safe levels.

- Installation recommendations

- Dynamic study of rigid, flexible, and pile foundation under harmonic, transient, and random loading.

- Geotechnical modeling of the soil mass, damping, and stiffness characteristics.

- Operating deflection shapes (ODS) on foundation repair/troubleshooting projects.

- Structural design of foundations, including concrete blocks and piles.

1.3 Customer Benefits

- Optimization of the foundation design based on foundation performance and construction costs.

- Elimination of foundation failures – extremely costly problems for owners.

- Dynamic foundation design – an integral element of a vibration mitigation strategy.

- Lower maintenance costs and improved safety –properly designed foundations reduce stresses on bearings.

- Reduced failure of auxiliary equipment including small-bore attachments .

|

|

|

|

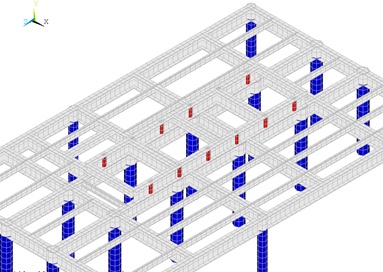

Examples of foundation design and dynamic analysis.

Top left: compressor, skid and foundation design provides an integrated approach and reliable results.

Top right: concrete foundation dynamics.

Bottom pictures illustrate pile foundation design and dynamic analysis.

2 Wood Advantages

Wood’s expertise in machinery design and dynamics, combined with in-house experts is unique.

Foundation services compliment Wood’s pulsation, mechanical, torsional, and skid design, resulting in an integrated solution.

Few other firms have this broad range of design expertise:

- Combination of geotechnical engineering with in-depth knowledge of machinery behavior

- Comprehensive machinery and foundation models

- Extensive field experience resolving existing foundation problems

- Inclusion of dynamic loads from equipment (gas rod loads, unbalance, pulsation-induced forces in vessels, etc.)

- Database of detailed reciprocating compressor models to accurately simulate system loading and response. Models have been verified with field testing

3 Related Information

- GMRC Guideline for High Speed Compressors (GMRC Website)

- Foundation Analysis and Design for Reciprocating and Rotating Equipment (pdf)

- Foundation and Skid Design Consideration For Large, High-Speed Reciprocating Compressors (pdf)

4 Related Services

- Skid Design and Analysis

- Structural Vibration and Dynamics Design

- Reciprocating Compressor – Pulsation and Mechanical Analysis

- Vibration Inspection Program

|

|

|

| Compressor Foundation Design (installation and field testing) |

Inspection of pile - skid connections as a part of modification to an existing foundation (to increase dynamic stiffness) |

Compressor foundation failure |

|

|

||

| Example 1: Gravel foundations impacts vibration High vibrations were measured on the skid and compressor package. An operating deflection shape (ODS) analysis determined that there were several local bending modes of the compressor skid as well as many modes of the piping, vessels and compressor cylinders in the range of the first and second order of compressor speed. Soil and gravel pad properties were evaluated with the compressor skid model to address the resonant condition. |

Example 2: Torsional vibration on piles When a pile supported compressor foundation was experiencing excessive torsional vibrations, we were able to mitigate these vibrations without using additional piles or imposing very high cost for removal of the compressor skid from the top of piles and moving it back. Using a unique solution, we increased the torsional stiffness, resolving the foundation vibration problem at a fraction of the expected cost. |

5 Key Words

- Dynamic Foundation Study

- Pile foundation design

- Foundation resonance

More Info

Webinar: Vibration problem solving – back to basics • Multi-channel vibration measurements • Five simple methods to check reciprocating compressor performance • Webinar: Feeling the pulse • Design Requirements for Reciprocating Compressors • Machinery Condition and Performance Monitoring • Evaluating Compressor Operating Risks • Tips for Managing a Successful Vibration Project • Specifications •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now