Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Review & Design Support Services

Vibration and Integrity Review; FEED, Project Planning

Vibration creates significant risks for an organization such as piping failures, loss of containment, and machinery downtime. As a trusted adviser and engineering consultancy, Wood – vibration, dynamics and noise (VDN) can help customers identify and mitigate these risks.

For new projects, including brownfield projects, our Vibration Review and Design Support can range from a few days of advisory services to a longer term strategic support role working closely with different teams. This small investment in engineering support has a large return to your organization.

Contents [ hide ]

1 Addressing Vibration is a Management Challenge

The consequences of vibration problems are significant and can lead to fire, explosions, injuries, downtime, maintenance costs, and environmental damage. Given these risks, owners are now much more proactive in addressing vibration issues, including vibration-induced fatigue failures on piping and machinery systems.

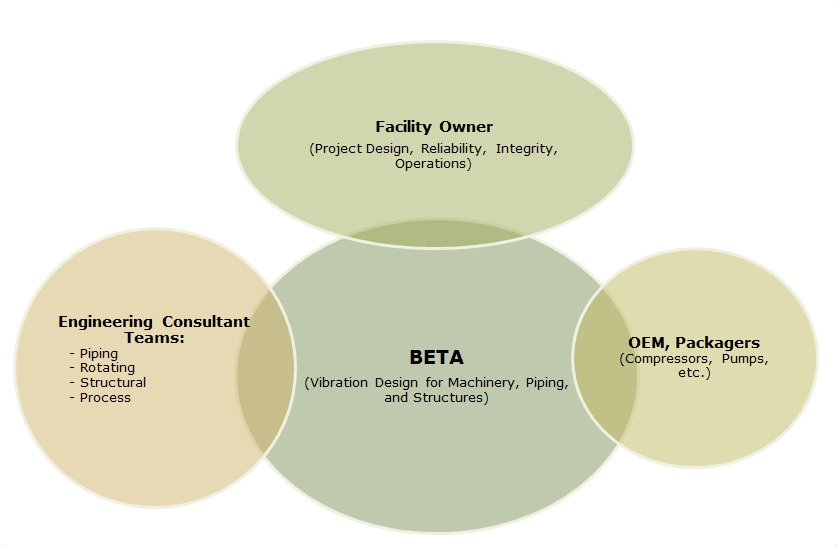

Vibration cuts across many different engineering functions, including piping design, integrity engineering, rotating engineers, structural engineering, and process engineering. Ensuring the vibration issues are integrated across these groups represents a management challenge.

This service is a proven approach to ensure vibration and dynamic engineering methodologies are conducted in parallel with the traditional design tasks, including static, mechanical and process design.

The real value of Wood’s role will be to ensure that recommendations are coordinated and integrated with the different stakeholders and a closed-loop process – including site assessment and continual improvement – is provided.

By working directly with the owner, Wood VDN (formerly BETA) can coordinate the advanced engineering requirements.

2 Vibration Review & Design Services - Scope

Wood's technical and advisory services will provide a roadmap and recommendations to minimize vibration integrity-related risks for:

- New Projects such as upstream production facilities (including offshore FPSO or platforms), compressor or pump stations, or downstream facilities (including refineries).

- Brownfield Projects such as facilities expansion or modification, Enhanced Oil Recovery (EOR) projects, or other situations where rotating/reciprocating equipment is changed.

- Existing facilities where the owner needs to assess its risks or to address ongoing reliability machine or piping problems. This can include commissioning or integrity assessment surveys.

These services include:

- Project review and advice during the FEED or planning stage. This includes piping layout, machine considerations, integrity considerations, and recommendations for implementation during detailed design and commissioning.

- Risk based assessment for a production facility. This assessment uses industry methodologies, such as the Energy Institute Guidelines.

- Design audit

- Assess process changes, layout changes, or structural/mechanical changes and their effect on vibration.

- Site visit to assess risks, which can include assessment of steady state and transient issues.

- Root cause analysis services

- Training on vibration/dynamics

- Or other customer specific needs requiring expertise in vibration and dynamics.

In this role, Wood provides independent support to the owner and its engineering team. Early involvement can save costly changes later in the design, and avoid expensive field modifications.

While the above services are most useful during the FEED or design stage, we also provide support during commissioning, operations, and life extension phases of your facility.

| MANAGING VIBRATION / DYNAMIC ISSUES - from Design to Operations | ||||

|---|---|---|---|---|

|

|

Design - Greenfield & Brownfield Projects |

Operations & Maintenance |

||

|

Feasibility Definition

|

Detailed Engineering Construction

|

Start-up; Commissioning

|

|

|

|

Wood VDN's Role |

Define:

|

|

|

|

3 Wood Advantages

When investing $ millions (or $ billions) into your next capital project, you want to ensure reliability and integrity risks are addressed. Wood’s services will provide the design and operational assurance you need.

Wood VDN’s team has over 1000 years of combined experience in solving complex vibration/dynamic issues. Few if any organizations have this depth of knowledge.

The combination of our field and design experience is unique, and provides major benefits to our top tier customer base:

- Wood’s field engineers have successfully solved 1000s of different vibration problems. Field-based experience, on a global scale, is crucial. It identifies real issues that should be avoided in the design stage.

- Advanced simulation, dynamic modeling tools, and other methodologies can be used to evaluate piping and vibration response. This advanced analysis can ensure the design will run smoothly across the range of operating conditions.

Long-term customers continue to trust Wood, including Shell, Chevron, Mobil, Williams Pipeline, Anadarko, TransCanada, CNOOC, PETRONAS, and hundreds of other industry leaders.

4 Related Information

5 Key Words

- FEED Study

- Vibration Audit

More Info

Webinar: Shake, rattle and grow I (2022 update) • Structural Vibration and Ways to Avoid It • Tips for Managing a Successful Vibration Project • Example: Offshore Pump Package (Video) • Structural Vibration from Compressor (Example) (Video) •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now