Products

Vibration Absorbers

Proven to reduce resonant vibration in piping and machinery

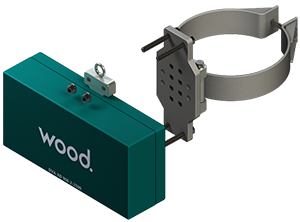

In conjunction with the Gas Machinery Research Council, Wood has developed the DamperX™ vibration absorber (DVA).

This rugged absorber is ideal for existing compressors, pumps or piping systems experiencing high vibration due to resonance.

It can be installed at the design and construction stage to avoid high vibration at resonance.

|

|

Based on further research, Wood has released a new DamperX™ vibration absorber with extra damping (DVA-XD).

This model has all benefits of a standard DVA with the advantage of reducing variable-frequency excitation such as variable-speed machinery and broad-band excitation sources like flow-induced turbulence (FIT) in piping.

Major operators rely on Wood's tuned vibration absorbers due to their long-lasting effectiveness, ease of installation and low cost.

How to order

Ask a question or get a quote Book a call with a specialist

You can also reach us at products.vdn@woodplc.com or call a local office.

For specifications and model numbers, download the cut sheet

Contents [ hide ]

Video

Applications

|

|

The DamperX™ vibration absorber (DVA) and the DamperX™ vibration absorber with extra damping (DVA-XD) can be applied to vessels, piping, and other resonant locations. For reciprocating compressor packages, a common application is near the top of resonant scrubbers or piping near coolers or PSVs.

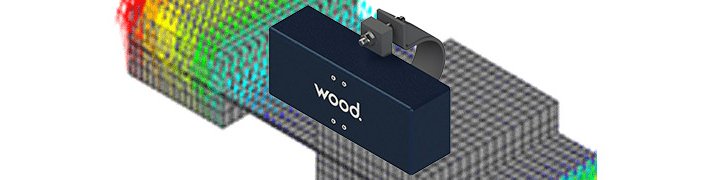

The damped vibration absorbers reduce vibration using a tuned mass and spring configuration. The absorbers won’t fail from excessive vibration, nor will they need any maintenance. It can be installed “hot,” an important advantage for many operators.

The DVA and DVA-XD are mounted in place:

- With a band clamp (supplied as standard)

- Attached to mounting tabs on equipment

- By a magnetic mount for temporary testing applications

How do vibration absorbers work?

Although new to the market, tuned vibration absorbers are based on well-known physics. Wood's vibration absorber has been developed in conjunction with a reputable partner (GMRC) and has been built, tested, and proven to work effectively in multiple field tests.

At resonance, the DVA and DVA-XD have been field-tested and proven to reduce vibration up to 95% from base levels.

|

| Impact test example |

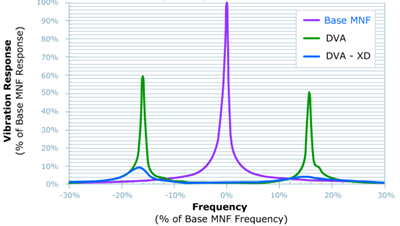

To achieve maximum performance, the vibration absorber unit is tuned to the target frequency. Once installed, the DVA or DVA-XD split the base mechanical natural frequency (MNFs) into two new MNFs, one higher and one lower than the base MNF.

How effective are vibration absorbers?

At resonance, Wood's vibration absorbers have been field-tested and proven to reduce vibration significantly, in some cases as much as 95% from base levels.

The standard DVA can achieve a 50% reduction in vibration amplitude. The goal of the device is to reduce vibration to acceptable levels – not eliminate vibration.

The DVA-XD further reduces vibration by more than 90% and is also effective for variable-frequency problems.

|

| The effectiveness of the vibration absorber has been proven in extensive tests and field applications |

How long do they last?

One unique feature of DVAs is their infinite life cycle. The designs have no stress concentrations in the spring component. This ensures a reliable, long-lasting solution to heavy-duty industrial applications.

What are the costs and installation requirements?

By comparison to other vibration solutions, the total cost of applying a vibration absorber is small. No modifications are needed to the piping, vessel, or skid. No supports are required. The unit can be installed quickly in minutes, without special tools or equipment.

Benefits

- Ideal for reducing vibration caused by resonance

- Robust design for high-vibration applications

- Versatile application on a wide variety of piping systems, vessels, and equipment

- Field-adjustable for maximum performance

- Can be installed “hot” – avoiding the need for equipment shutdowns

Advantages

- Cost-effective, simple design

- Easy to install

- No braces or supports required

- No maintenance required

- Long life expectancy

- Standard designs available to suit most applications (contact us for application assistance or customized solutions)