Depending on the project, we can reduce processing and reporting costs by up to 60% – a significant competitive advantage. This is especially useful when collecting large amounts of field data, such as with multichannel systems with many operating conditions.

Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

PostPro – field data processing and analysis

Reducing field data analysis and reporting time

PostPro allows us to quickly process, analyze and report findings when collecting field measurements, including vibration waveform, pressure and other data.

Analyzing large amounts of test data is very time-consuming. For example, multichannel data acquisition systems often record up to 240 channels, potentially with multiple operating or load conditions. This may generate hundreds of gigabytes of data, taking days or weeks of effort to sift through the data, performing repetitive processing tasks, 'searching for the needle in the haystack.'

PostPro dramatically cuts down this labor-intensive work from days to hours.

Benefits for our customers (click to expand):

[ACCORDION_1]

Contents [ hide ]

1 The data challenge with troubleshooting projects

|

|

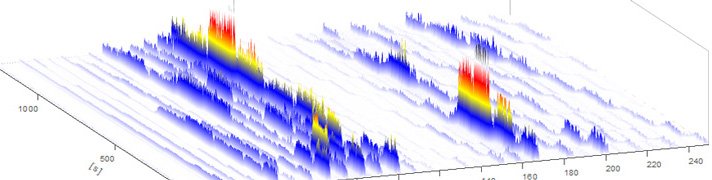

Multichannel vibration setup for compressor station (4 to >200 channels). PostPro analyzes the results and provides unique insights into the system’s reliability, helping manage operational risks. Multichannel analyzers record how the entire station reacts during different scenarios. This produces more reliable data, can capture transient events and gives the operator greater freedom from needing to sustain specific operating scenarios while the measurements are taken. |

Wood is the leading consultancy for vibration troubleshooting, due to our global coverage, competency, experience and innovative solutions. Our team is involved across all industries, assessing problems on piping, structures and machinery systems.

While at site, we measure vibration, pressure pulsations, strain, stress and other data at many different locations, varying operating conditions and times. This results in large datasets of complex vibration waveforms (gigabytes of data, hundreds to thousands of files).

Post-processing this data is time-consuming and impractical without automated tools like PostPro. For example, manual processing of data for small jobs may take a few days, while for larger, more complex projects it can take weeks. This challenge creates extra costs and delays for the customer.

Another data challenge is accuracy. Manual searching through the data can result in errors, such as missing an important vibration peak or transient issue. The manual approach may miss important patterns or linkages between different test locations or conditions. Sorting through this data is analogous to the “needle in the haystack” problem.

Read more about multichannel field data collection

2 What is PostPro?

PostPro is a proprietary software tool developed and used by Wood’s field engineering and troubleshooting team. It was developed as part of a multi-year research project to address the data analysis challenges (see above) and gaps in technology from traditional analyzer equipment software.

3 Benefits

Lower project costs - thousands of dollars in savings

- Depending on the project, we can reduce processing and reporting costs significantly – a unique competitive advantage

- Saves days (and sometimes weeks) of engineering time, especially when using multi-channel acquisition systems, long-time capture or when many test points or conditions need to be analyzed

Faster results

- Allows us to provide better service to our customers, with timely recommendations

- Ability to view results at site and provide preliminary information about risks and possible solutions

Higher accuracy

- PostPro eliminates common errors that occur when manually analyzing large datasets

- Quality control procedures embedded in software

- Field verified from hundreds of projects

4 Features

|

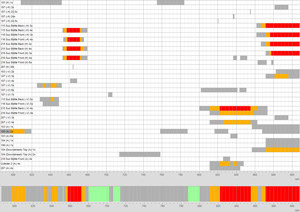

| A 'speeds-to-avoid' chart helps operators run equipment at safe levels and avoid downtime |

Inputs:

- Vibration

- Pressure or current pulsation

- Stress or strain

- Machine speed, RPM

- Operating conditions

- Other data sources

Speed:

- Quickly processes data by automating repetitive tasks, dramatically reducing analysis time

- Pre-configured plots, reports and templates

Plotting:

- Spectrum, waterfall and 3D plotting

- Spectrum order tracking analysis and plotting provide additional insight into potential sources of problems

- Speeds-to-avoid charts. These charts are critical for pump and compressor projects where the operator needs to know the safe operating speed ranges for the equipment (to avoid failures)

- Time-domain averaging and plotting, comparisons to various guidelines

- Summary reports highlighting locations that exceed guidelines, providing a summary of problem areas to focus on for advanced testing. This helps to understand the root cause of vibration or performance issues and to find a practical recommendation to solve the problem.

Flexibility:

- Configurable to any vibration, pressure pulsation or stress guideline (custom or standard)

- Plots and summary reports can be exported in engineering units of your choice, simplifying the report review and readability

- Works with many commercial data analyzers (independent from equipment OEMs) while standardizing the output

- Customizable for unique project requirements

Contact and more information

Article: Multi-channel vibration measurements (CompressorTECH magazine, PDF)

Article: Catching the waves

-

Lower project costs

-

Faster results

We can deliver superior service by providing timely information and recommendations. Often, we can provide preliminary results while at site including anomaly reports compared to guidelines, speeds or load conditions to avoid, and other information that may affect your operations.

-

Higher accuracy

PostPro eliminates common errors that can occur with manual processing or analyzing large datasets, eliminating the rework and missing potentially important data.

-

Practical multichannel, multi-condition field testing

PostPro makes multichannel data collection and analysis including several operating conditions and loads possible due to its inherent post-processing and analysis capabilities. This type of analysis was not practical without an automated software approach.

Related Pages

Field engineering and troubleshooting • Multi-channel vibration measurements • Troubleshooting, Root Cause Analysis (RCA) • Machinery Condition and Performance Monitoring •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now