Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Pipe Stress Analysis

(Thermal Analysis, Piping Flexibility Analysis)

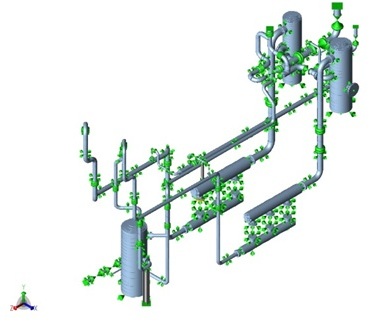

A pipe stress analysis (thermal flexibility analysis) predicts stresses in piping and loads on equipment resulting from thermal gradients, thermal transients, weights, pressure, and bolt-up strain. This study is typically required for piping that experiences high temperature fluctuations, or for long pipe runs such as hot piping to coolers or headers. Cases where equipment is sensitive to external loads may also require a pipe stress analysis.

The study methodology becomes more complicated for piping systems in vibratory service. As discussed below, the design must address conflicting requirements between the pipe stress analysis (where flexibility is desired) versus the mechanical vibration analysis (which requires stiff supports). Methods are available to manage this conflict and create an optimal piping design.

This link provides a general overview of static and dynamic piping design requirements:

Piping Vibration Design Considerations (Static and Dynamic)

Contents [ hide ]

Free webinars

Stress relief

Stress relief

Learn when a piping stress/flexibility analysis is required, which codes and factors to consider and how to avoid common mistakes to ensure a safe design.

Shake, rattle and grow

Part I:

Learn how to balance the requirements for both effective vibration support and sufficient piping stress flexibility using our latest pipe stress analysis tools and techniques.

Part II:

Part II:

Learn how to select the right pipe clamp for vibration and thermal growth applications.

1 Scope

This analysis calculates piping stresses resulting from thermal cycles, pipe and fitting weights, and static pressure for the main process piping. Generally, CAESAR II is used for modeling the system, although other specialty computer programs such as NozzlePRO and FETee are sometimes required.

- Evaluates stress due to thermal cycles, weight, and static pressures in the piping as per all industry piping codes, such as B31.3, B31.8, CSA Z662, BS826, BS7159, FDBR, DNV, Stoomwezen and others

- Calculates loads on equipment (e.g., vessels, coolers, pumps, and compressors) and designs them to meet industry standards

- Recommends pipe layout, pipe support, and clamp designs

2 Options

- Assessment of piping system subject to environmental loads (wind/seismic)

- Design piping system to withstand PSV discharge loads

- Detailed analysis of vessel nozzle loads to meet ASME Section VIII, Div. 2 pressure vessel stress requirements

- Design cooler nozzle loads to meet strict API 661 requirements

- Analysis of underground or buried pipe

- Fatigue analysis of high pressure piping per ASME B31.3, Section IX

3 How to avoid conflict between pipe stress and vibration requirements

When machinery is involved in the piping system, the same consultants performing the dynamic mechanical finite element analysis (FEA) should also complete the Pipe Stress Analysis. This will avoid conflicts between stiffness assumptions and requirements for supports, and also expedite a solution. Typically, dynamic mechanical analysis will specify high stiffness supports, while piping flexibility analysis will require flexible supports. It is important to simultaneously consider both static and dynamic requirements.

- Controlling vibration, and vibratory stress typically involves restraining the pipe. It also requires closer spacing of pipe supports (between clamps) to raise the mechanical natural frequency of the pipe to avoid resonance. Vibration control standards also require that pipe supports have enough stiffness to stop vibration at the support and caution against the use of hangers and guides.

- A pipe stress analysis mitigates static deflections and stresses and typically involves selectively providing flexibility with a mixture of rest supports, guides, line stops, hangers, spring supports, and hold downs.

- Recommendations for the pipe stress analysis can be directly opposite to the vibration design requirements. This conflict can, and does, result in significant confusion and problems during construction and operations.

To avoid this conflict, the standard industry approach is to have the same consultant perform both the vibration analysis and the piping stress analysis. This ensures the vibration control and piping design are adequately addressed, including realistic pipe support stiffness assumptions, and use of vibratory clamps/restraints that have enough flexibility for thermal growth (see articles below for more info).

4 Wood advantages

- Our practical recommendations are based on more than 50 years of field and design experience. Having machinery and field experience provides many practical advantages when evaluating the piping design

- Our analysts are experts in the latest analytical software for pipe stress analysis including ANSYS, CAESAR II, NozzlePRO, FETee/FESIF, and other applicable software packages. Wood's software tools provide more accurate stress intensification factors resulting in better results (less conservative recommendations)

- FEA and field testing ensures accurate boundary conditions for the

computer simulations; especially valuable are accurate stiffness assumptions for piping supports

computer simulations; especially valuable are accurate stiffness assumptions for piping supports - Our proprietary piping restraint designs accommodate vibratory loads as well as thermal expansion

- Our proven approach to address dynamic and static designs avoids conflicting recommendations and approaches between thermal and dynamic/vibratory requirements

- We have a comprehensive piping analysis offering that covers FIV, AIV, Energy Institute, surge, water hammer, etc

- With offices and support in many regions, we offer responsive global support

- Our depth of engineering resources supports any size project

- Our pricing is competitive

5 Customer benefits

- System designs ensure safe operation

- Extend equipment longevity and minimize maintenance costs through appropriately balanced thermal and dynamic support requirements

- Minimize number of pipe layout and support revisions when Wood conducts the piping flexibility study and API 618 DA2 and DA3 mechanical studies

6 Pipe support design guide

Download our practical design guide for pipe stress engineers:

7 Related information

- Recommended Approach to Piping Flexibility Studies to Avoid Compressor System Integrity Risk, Kelly Eberle, GMC 2011 (PDF)

- Improved Thermal Piping Analysis for Reciprocating Compressor Piping Systems, Chris Harper, GMC 2012 (PDF)

- Pipe Support Stiffness, GMRC research overview, 2014

- Training class Piping Systems: Techniques to Mitigate Vibration (pdf)

8 Related services

- Piping Vibration and integrity Assessment

- Troubleshooting (Machinery Pulsation and Vibration Problems)

- Anti-vibration and thermal-growth clamps

- Piping Systems (general information static and dynamic piping analysis)

9 Keywords

- Thermal flexibility

- Piping flexibility

- B31.3

- API M11 study

More Info

Webinar: Shake, rattle and grow (2022 update) • Webinar: Controlling dynamic flexibility • Webinar: Piping and tubing vibration anomaly mgmt • Webinar: Downstream performance optimization • Pipe support performance – ask the expert • Multi-channel vibration measurements • Vibration-induced fatigue management (Offshore Magazine) • Webinar: Shake, rattle and grow I (2022 update) • Avoiding vibration-induced fatigue failure • Examples of Piping Vibration (Video) • Pipe Support Stiffness, GMRC Project • Transient Conditions on Small-Bore Piping • Piping Vibration Design Considerations • Tips for Managing a Successful Vibration Project • Piping Vibration Examples • An Integrated Approach to Manage Vibration Risks •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now