Knowledge Center

- Downloads

- Technical Newsletter

- Recommended Guidelines and References

- Specifications

- Technical Papers

- Tools and Calculators

- Training

- Articles, Tips and Requirements

- An Integrated Approach to Manage Vibration Risks

- Design Requirements for Reciprocating Compressors

- Evaluating Compressor Operating Risks

- Five simple methods to check reciprocating compressor performance

- Important Differences in Pulsation Software

- Liquid Pumping Systems (Including Liquid Pipelines)

- Noise Regulations Around the World

- Noise Risks in the Gas Industry

- Performance Monitoring Examples

- Pipe Support Stiffness, GMRC Project

- Piping Vibration Design Considerations

- Piping Vibration Examples

- Structural Vibration and Ways to Avoid It

- Tips for a Successful Project (Vibration Control)

- Transient Conditions on Small-Bore Piping

- Vendor Requirements for Piping Vibration & Integrity Assessment

- Vibration-induced fatigue (whitepaper)

- Vibration Issues Affecting Gas Compressor Facilities

- Ask the expert

Transient Conditions on Small-Bore Piping

This update highlights one question that often comes up regarding transient vs. steady state vibrations.

Is it important to evaluate transient operating conditions on small-bore piping?

Failure of small-bore piping (SBP) continues to be the number one failure we see on many machinery packages – both liquid pumps and gas compressors. SBP refers to relief lines, drain piping, sight glasses, and small appendages attached to main process lines – typically two inches or less in diameter. A gas or liquid release at a facility will generate untold losses such as staff safety consequences, environmental remediation, public exposure, increased regulatory costs, and of course, downtime.

In our definition, a transient condition includes:

|

| Vibration Audit on Small-Bore Piping |

- The start-up and ramp up of a pump station

- Shutdown including ESD events

- Throttling of a pressure control valve during a temporary condition or other seldom run conditions

Why worry about transient conditions?

There are a couple of reasons:

- First, many operators often do a vibration check on rotating machines and the piping system. These checks are typically performed during steady state operations and do not include testing during a transient event. This means the operator is not aware of vibration risks during these events.

- Second, the design of SBP is hit and miss. In many situations, the design of SBP is left up to the installers in the shop or field. The result can be an inconsistent approach to SBP design standards. In other cases, the design team may evaluate the SBP design, but the design may be based on steady state conditions and may not evaluate the range of transient conditions.

High Transient Vibrations

Here is an example that illustrates the risk. During a field inspection for a pumping facility, Wood measured vibration across steady state and transient conditions. A multichannel analyzer is used to assess SBP vibration at key locations. The data is captured across a long time period and specialized software is then used to process and analyze the results.

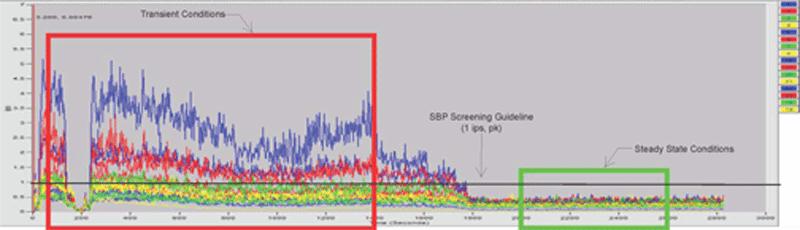

The chart below illustrates just one of many results from different customer locations. The vertical scale is overall vibration amplitude (inches per second peak). The horizontal scale is time (seconds). The vibration screening guideline is also shown as a black horizontal line. Each color represents a different test point in the station. For simplicity, only 16 channels of the 56 channels of data captured are shown.

The red box illustrates high vibration measured while testing different transient events. The vibration levels significantly exceed the guideline. In this case the transient events measured will occur several times per month, thus increasing the risk of failure over time.

Is this a Reliability Risk?

Transient vibrations may be tolerated if they seldom occur. However, if the transient event happens on a regular basis, the risk of fatigue failure should be considered. Depending on the frequency of the vibration and stress levels during the transient event, it may only take a few hours for the SBP to achieve enough cycles to cause a crack.

This example illustrates how transient conditions can be a culprit in SBP failures. Wood’s Vibration Survey, or baseline assessment, is a good way to identify SBP vibration risks and can include testing during transient operations.

Related Pages

Examples of Piping Vibration (Video) • Pipe Support Stiffness, GMRC Project • Piping Vibration Design Considerations • Tips for Managing a Successful Vibration Project • Piping Vibration Examples • An Integrated Approach to Manage Vibration Risks •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now