- No advertisements

- Your data is strictly confidential to you

- Why free? Our hope is that you find value in using it and when you need help you might think of us.

Services

- Static Equipment & Structures (Piping Vibration & Fatigue)

- Acoustic Fatigue Assessment for Blowdown Systems

- Acoustic-Induced Vibration (AIV) Analysis

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Flow-Induced Turbulence (FIT) Analysis

- Flow-Induced Vibration (FIV) Analysis

- Multiphase and Slug Flow Analysis

- Pipe Stress Analysis

- Piping Vibration and Integrity Assessment

- Review & Design Support Services

- Small-Bore Connections (SBC) Assessment

- Structural Vibration and Dynamic Design Analysis

- Subsea Piping Vibration

- Thermal Striping

- Tube Failure Analysis

- Veridian AM

- Veridian VS

- Vibration Inspection Program

- Water Hammer Analysis

- Machinery Analysis

- Bottle Sizing Service

- Compressor Package Engineering

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Foundation Design and Dynamic Analysis

- Fuel Gas Compressor Piping Transient Analysis

- Lateral Vibration Analysis

- Pipe Stress Analysis

- Pulsation & Mechanical Analysis: Reciprocating Compressor

- Pulsation & Mechanical Analysis: Reciprocating Pump

- Pulsation & Mechanical Analysis: Screw Compressor

- Pump RCF Analysis

- Review & Design Support Services

- Shell Transverse Acoustical (STA) Analysis

- Skid Design and Analysis

- Surge Control Design for Centrifugal Compressor Systems

- Torsional Vibration Analysis (TVA)

- Field Engineering & Troubleshooting

- Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD)

- Human Vibration

- Motion Amplification Vibration Analysis

- Noise Troubleshooting

- Performance Assessment (Thermodynamic)

- PostPro – field data processing and analysis

- Structural Vibration Troubleshooting

- Thermal Striping

- Troubleshooting, Root Cause Analysis (RCA)

- Veridian iDAC

- Vibration Inspection Program

Veridian VS

Vibration screening can now be done quickly and efficiently with significant cost savings for operators.

Veridian VS is a free, web-based screening tool used by owners, operators and engineering consulting firms to identify high-risk locations in process piping systems. This stand-alone tool is used to improve the design of piping systems, to support inspection and measurement activities, and for vibration integrity programs.

Contents [ hide ]

Benefits

Click to expand for more details:

[ACCORDION_1]

Uses for Veridian VS

|

|

|

|

|

|

Risks evaluated by Veridian VS

Veridian VS identifies and evaluates potential excitation mechanisms that can result in piping vibration fatigue failures, such as:

- Flow-induced turbulence (FIT), including multiphase excitation

- Mechanical excitation from connected or nearby machinery such as reciprocating compressors or centrifugal pumps

- Pulsations caused by reciprocating pumps and compressors

- Pulsations caused by centrifugal compressor rotating stall

- Flow-induced pulsations caused by deadlegs in the piping system (deadleg pulsations, FIP, or FIE)

- High-frequency acoustic energy created by pressure reducing devices (AIV, AIE)

- Transient-caused valve operation (surge, water hammer, relief valve reaction forces)

- Cavitation and flashing of liquids

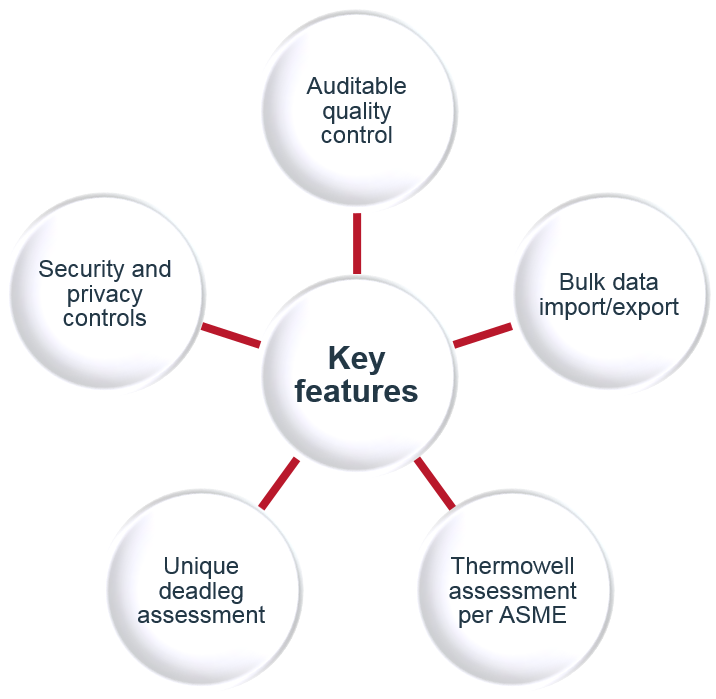

Features

|

|

Other features include:

|

| Easily identify and evaluate all potential excitation mechanisms | ||

|

||

| User statistics, auditing | Define access for team members | Unique evaluation for subsea flowlines (flow-induced pulsation) |

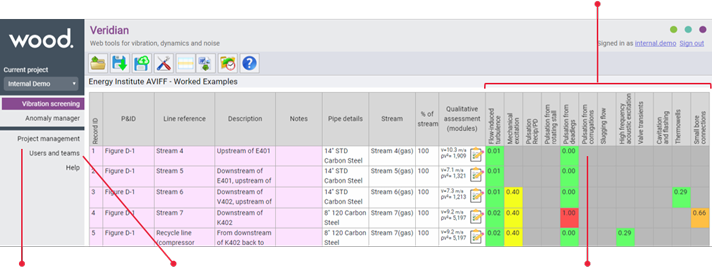

Examples

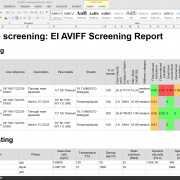

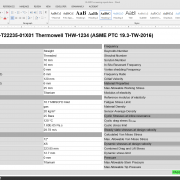

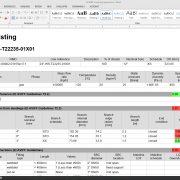

| Screening report – line listing | Detailed listing | Detailed assessment table |

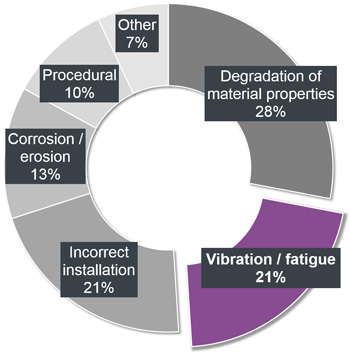

Why screen for vibration risks?

Industry research confirms that vibration-induced fatigue failures are a major source of fluid release in hydrocarbon facilities1. These failures are costly in terms of safety, environmental damage, corporate liability, extended downtime and financial losses.

|

1 Source: UK Health and Safety Executive |

API integrity management standards (API 570,571, 574 and 584) consider vibration as an important damage mechanism that requires proactive management for all small-bore connections (SBCs) and piping.

Get started with a free account

Video tutorial – how to set up your first project

2019 new features and improvements

New features and improvements in Veridian 1.3 include:

Void fractions are only used if you select the EI Guidelines 2020 (which is not yet available).

- Linked vibration screening and anomaly management modules

You can now link vibration screening assessments to an anomaly in Veridian AM - AIV improvements and more save options for AIV models

- Add comments to each save (visible in revision history) or lock a model to prevent further edits

- Enter a value for a low noise trim on a PSV or source

- Notes field on items

- Improved copy/paste

- Menu bar clean-up

-

Improved scrolling through results

- Nexus integration – sync LOFs to Nexus Integrity Centre

- Void fraction for vibration screening

You can now enter either phase or a void fraction in the VS Streams section. If you enter dry gas/wet gas/multiphase/liquid it will guess the void fraction.- Gas has now been changed to “wet gas” with a void fraction of 0.96.

- Multiphase assumes a void fraction of 0.80

- Liquid assumes a void fraction of 0.02

- Dry gas assumes a void fraction of 0.99

- New bulk import options and spreadsheet for anomaly manager

The bulk importer now makes it much easier to enter multi-dimensional data, and you can import anomalies, surveys, measurements and recommendations separately. Talk to us to find out more about this.

Related information and resources

Download the Veridian fact sheet (PDF)

Read the Veridian FAQ

Veridian overview

Whitepaper: effective piping vibration management

Piping vibration integrity primer (PDF)

Case study: managing piping vibration integrity risks at an LNG facility (PDF)

Technical papers:

AIV and FIV in Pipelines, Plants, and Facilities

International Pipeline Conference 2016, Calgary, Canada (© ASME)

Testing System Set-Up to Evaluate Acoustic Induced Vibration

ASME 2016 Pressure Vessels and Piping Conference 2016, Vancouver, Canada (© ASME)

Vibration-Induced Fatigue – A Risk-Based Approach

API Inspection Summit 2017, Galveston, TX, USA

Authorities regulating vibration:

- Australia: NOPSEMA

- Norway: Petroleum Safety Authority

- UK: HSE Energy Division

- US: Bureau of Safety and Environmental Enforcement

Related services

Veridian AM – anomaly management

Piping Vibration and Integrity Assessment

Acoustic-Induced Vibration (AIV) Analysis

Flow-Induced Vibration (FIV) Analysis

Multiphase and Slug Flow Analysis

Small-Bore Connections (SBC) Assessment

-

Free tool. Available to people inside and outside your organization.

-

Web-based. Easy to access and share.

- Easy access for all your team members

- Improves visibility to integrity risks

- Improves collaboration

-

Secure, private, consistent. Data from all projects and assets saved in one secure tool and database.

- Data from all projects and assets in one secure location

- Supports any sized facility

- Accommodates multiple assets, facilities and projects

- Global access to all your assets

- Your data is confidential and secure

- Users define access and security controls over project data

- Our team does not have access to your project details unless given access for support or advice. [see license agreement for more details]

-

Improved quality, efficiency and easy to use. Over traditional spreadsheets or hand calculations.

- Avoid errors, inaccurate assumptions

- Improve the quality control and auditing process

- Minimize overly conservative designs and associated costs

- Improve efficiency for large systems (eg, 1000s of lines and small-bore connections)

- Intuitive, fast, efficient evaluation and reporting

- Allows bulk importing of complex piping systems

- Exports to other analysis tools and speciality resources

-

Proven. Built and used by industry experts.

- Used extensively by Wood’s vibration team who provide specialized analysis services for machinery, piping, structures and noise requirements around the globe

- Ensures a robust product and gives you ready access to regional support with access to industry leading experts

-

No maintenance. We ensure the tool keeps pace with current standards and regulations.

- Veridian is continually updated with changes in vibration standards

- New features are added based on user input

-

Proactive. Provides best-practice management of vibration risks.

- Allows EPCs and operators to evaluate vibration risks in their projects or facilities

- Avoids the costly consequences of small-bore piping failures or other fatigue problems

-

Reduced design, construction and commissioning costs.

- Avoids design delays and rework by identifying piping risks early in the design phase

- Less conservative piping design equates to lower capital costs

- Screening database built in design phase is used during commissioning and inspection – a significant saving for inspection teams

- Vibration fatigue threats are properly managed, avoiding failures and loss of containment

-

Data custodian throughout your asset’s life cycle.

- Important vibration considerations uncovered at the design stage frequently fall through cracks at the commissioning and operating stages

- The Veridian vibration risk database links design, commissioning and ongoing inspection work, closing gaps between these project phases

- Veridian provides a living channel of information beginning at design, updated during commissioning and carried through lifecycle operations

-

Accordion test title

acc2 content

More Info

Webinar: Shake, rattle and grow (2022 update) • Webinar: Controlling dynamic flexibility • Webinar: Piping and tubing vibration anomaly mgmt • PostPro – field data processing and analysis • Multi-channel vibration measurements • Vibration-induced fatigue management (Offshore Magazine) • Webinar: Shake, rattle and grow I (2022 update) • Avoiding vibration-induced fatigue failure • Examples of Piping Vibration (Video) • Important Differences in Pulsation Software • Pipe Support Stiffness, GMRC Project • Transient Conditions on Small-Bore Piping • Piping Vibration Design Considerations • Tips for Managing a Successful Vibration Project • Piping Vibration Examples • An Integrated Approach to Manage Vibration Risks •

Free webinar

Learn how to solve complex vibration problems with advanced troubleshooting techniques to keep your facility running smoothly, with minimal downtime. Watch now